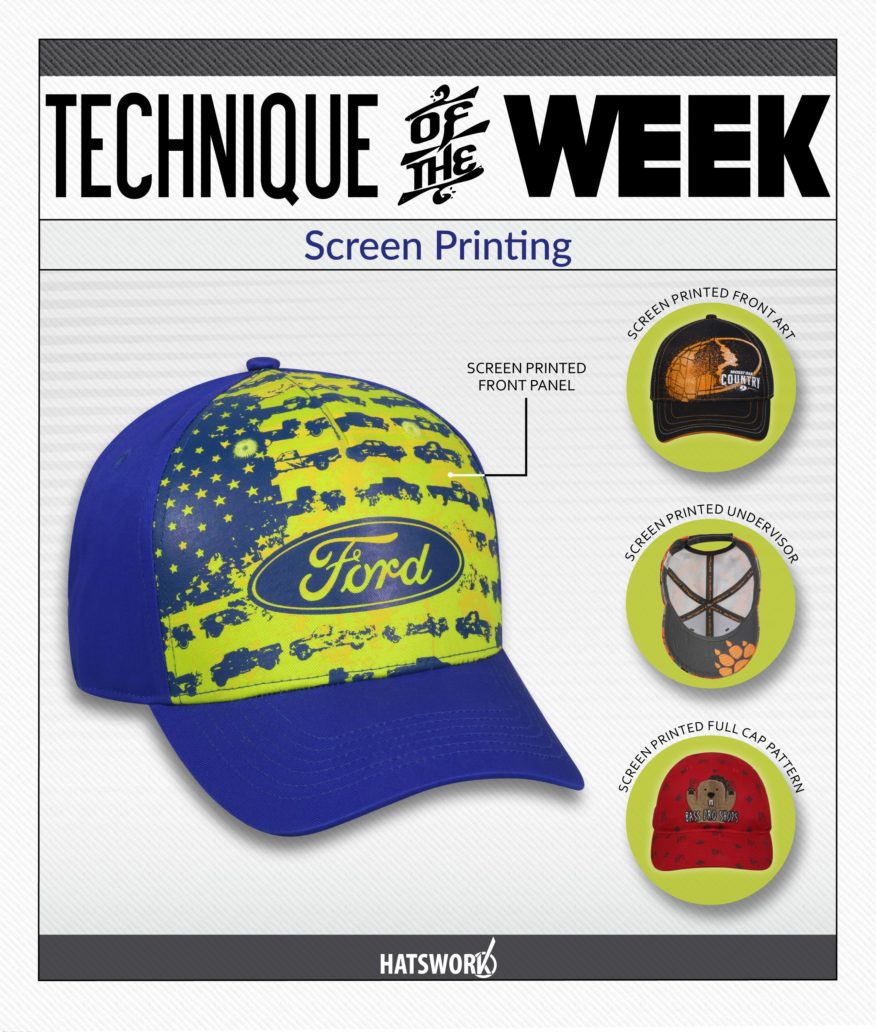

Continuing with our All About Headwear series, today we’re covering everything you need to know about screen printed hats in order to sell them to your customers.

Don’t forget to check all out all of our other decoration technique blogs: embroidery, water printing, and heat pressing.

Screen Printed Hats … And Other Stuff

Confession time. Before I began my research for this article, I was under the impression that screen printing was only used on fabric products: caps, t-shirts, canvas bags, that sort of thing.

I was so wrong. It’s used on all types of products including drinkware and pens. Who knew? Not me. Go figure.

Moving on from my ignorance, let’s jump into screen-printed hats!

First things first, screen printing is defined as the act of forcing ink onto a surface through a prepared screen of fine material so as to create a picture or pattern. BELLA+CANVAS has compiled a nice “dictionary” of screen printing terms that may be helpful if you’re not well versed in the art as I clearly was not.

In a recent survey conducted by ASI, 26% of respondents cited caps and headwear as popular screen printed apparel items.

Screen printing is one of the most inexpensive decoration techniques; so it should be an easy sell for your customers who are looking for high-quality headwear at an affordable price.

Things to Consider

If your customers are looking for fully customizable screen printed hats that will be completed overseas, you can disregard this section. All techniques including screen printing can be completed prior to assembling the cap so no additional requirements, equipment, or considerations are necessary.

If they’re ordering blanks with the intention of having them screen printed, pay close attention.

Equipment

Not all decorators or manufacturers will have the proper equipment or attachments necessary for screen-printed hats. In fact, only 56% of decorators offer screen printing at all, and the ones who do aren’t guaranteed to have the additional parts required for caps.

Screen printing presses are designed for products that lay flat such as T-shirts; so specialized accessories are needed to incorporate headwear. Check with your sales person to make sure caps can be accommodated.

Five or Six Panels

Six panel hats can be difficult to screen print because the screen can get caught on the seam that runs down the front center of the cap. This can affect the uniformity when placing a large order; some designs may be lower or higher on the cap. Because of this, five panel foam hats (also called trucker caps) are recommended for screen printed designs.

Another option for six panels is to apply a screen-printed patch. Patches can be placed virtually anywhere on the cap including over the center seam.

The Great Debate: Push or Pull?

A squeegee is used to either push or pull ink across the screen transferring it to the item below. There is a lot of dispute on when to use each method. So, here’s our take for all you decorators out there looking to get into screen printing.

Pushing is the more comfortable position of the two. It puts less pressure on the creator’s wrists because the strength of the entire upper body is used to push the squeegee to the far side of the screen. If the artwork has few details or requires a large amount of ink, the push method works just fine.

Pulling is generally the better choice because the creator can adjust the angle of the squeegee thus adjusting the amount of ink applied to the design. Pulling also gives the creator more control over depositing ink into detailed designs.

Each approach serves a significant purpose. Skilled creators will be well versed in both printing methods.

I sincerely hope I’m not alone in my misconceptions about screen printing and the products that allow for it. Feel free to comment if you were as oblivious as I was and maybe I’ll feel a little bit better about myself. You can also follow us on Instagram and use the hashtag #hatswork.