We’re getting back into our All About Headwear series. In the past we’ve covered the following topics—cap anatomy, sublimation, sizing and curvature, embroidery, customized cap orders, screen printing, and water printing.

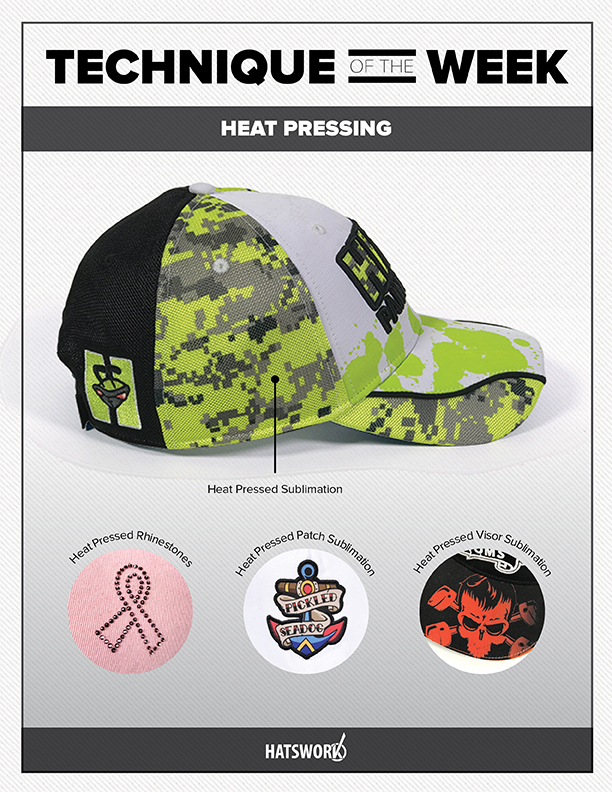

Today, you’ll learn how to heat press headwear.

Heat pressing involves any application that transfers material or ink to a surface using heat to force action and bond the final graphics. This can include any of the following:

- Vinyl

- Flock

- Glitter

- Foil

- Ink Jet

- Laser

- Rhinestones

- Sequins

- Plastisol (Partial-Cured Screen Print)

- Sublimation

To heat press headwear, you will need a hat press with specialized platens designed to fit inside the curve of the hat’s crown. The manufacturer of your heat press will offer a variety of sizes to accommodate different cap styles.

After selecting a proper-fitting platen, you will need to position the hat so that the sweatband is folded down and the cap is pulled tight with no wrinkles, loose fabric, or gaps between the cap and platen.

Some heat-seal materials will have an adhesive backing to hold the design in place during pressing. But if your design isn’t sticky, you can use thermal tape. This will ensure you maintain a high-quality, and well-positioned graphic.

Screen printing and water printing can be very difficult on headwear. Because of the curved nature and the center seam on 6-panel caps, it’s hard to print identical batches even with specialized attachments or tools.

Alternatively, it’s much easier to heat press headwear.

With a heat press, you can decorate any surface of the hat. Front, sides, visor, closure, even the top of a bucket hat can be decorated using a heat press.

Another advantage of heat pressing is the ability to run small batches. If your customer comes back after an order and decides they need a few extra caps, it’s not going to cause you a lot of additional time. You can press them in a matter of moments.

With screen printing, it’s almost not even worth the headache to prepare a screen for only a couple of pieces.

You can also print caps on-demand to save yourself some money. This way, you won’t have extra styles or colors in inventory that you can’t sell. You can press the exact number of caps per order—no more, no less.

For more information check out this video.

Is there a certain decoration technique you’d like to see us cover? Let us know in the comments below. Don’t forget to follow us on Instagram using the hashtag #hatswork.