Sublimation is a fairly new technique that has taken creativity of printable products to a new level, especially caps. Cap sublimation gives you creative freedom to create bold designs in vivid color that will showcase your company. With sublimation you can take any digital image, no matter the size or array of colors, and apply it directly to your product. Just imagine all the possibilities!

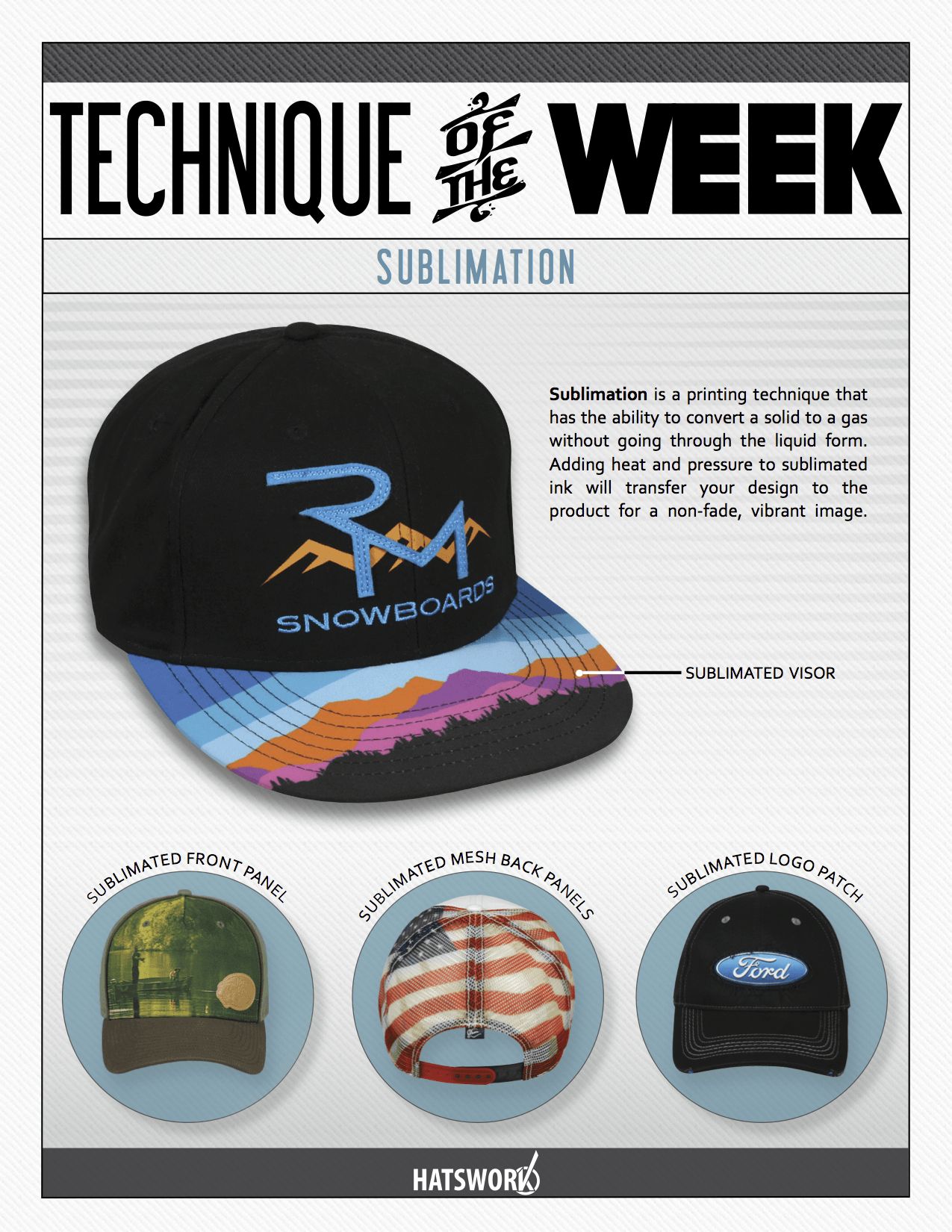

Here’s a simple example of cap sublimation:

So how does sublimation work? It’s pretty simple, actually. There are 2 steps that a decorator will take to make your artwork come to life.

First, they print your digital design on a special printer with sublimation ink and paper. Secondly, they place your design on a heat press that transfers the ink to your product. Wait a short minute or two and voliá! Your design is now imprinted to the fabric. This means no peeling off, or fading. The colors will stay vibrant even after multiple washes or sun exposure. This type of printing is great for teams or outdoor sports because of its nonfading qualities. Sublimation works really well on synthetic fabrics such as polyester.

Below are a few examples of different ways to sublimate your cap. The capabilities will depend on who you buy it from. You will have more options from a manufacturer than your local decorator down the street. For example, at the manufacturer level they can sublimate the whole front panel before the construction of the cap (see fishing hat below), but your local decorator will most likely be able to only sublimate a logo or smaller design. A good place for sublimation printing on a cap are the front panels, visor or undervisor. But hey, the possibilities are endless! Be creative, think outside the box, and start creating your unique design to be sublimated.

Download some examples of sublimated headwear below in this Hatswork PDF: